“Stop-Start” engines, how do they work?

Faced with ever increasingly demanding environmental standards, vehicle manufacturers have been forced into finding new ways of reducing vehicle CO2 emissions produced by the vehicles engine. Stop - Start systems are one of the most common systems developed to help reduce vehicle emissions.

What is a Stop–Start system?

When the vehicle is stationary at traffic lights a stop sign, or just general traffic the driver shifts the vehicle into neutral leaving the vehicle running ready to move on at some point, all the time using fuel and producing CO2 emissions. Stop-Start system goes a step further by shutting down the vehicle’s engine and automatically restarting it when power is required. The stop-start system puts the vehicle into a stand-by mode when the driver of the vehicle depresses the vehicles clutch pedal and putting the vehicle into neutral. The vehicle automatically restarts when the clutch is depressed, and the vehicle is put into gear.

Vehicles using a integrated starter-alternator require high belt tension

Some vehicles use the alternator as the starter motor rather than using a separate starter motor, this helps reduce the vehicles weight, this in turn helps reduce CO2 emissions.

Engine timing belts and auxiliary belts have specific tension requirements for the different operating modes of an engine.

A minimum and maximin tension must be maintained at all times in order to provide driving force to the accessory system components such as the alternator or the air conditioner compressor, without the belt slipping.

This means belt tension must never fall below a certain pressure to make sure the belt does not slip. A belt which is over tensioned can also cause the system to fail prematurely due to the excessive friction damaging the belt and tensioner roller bearings.

Systems that use the alternator as a starter motor require far higher tensions to be applied to the belt and pulleys to stop any belt slippage whilst the engine is being started. This extra higher tension puts a great strain on all the accessory system.

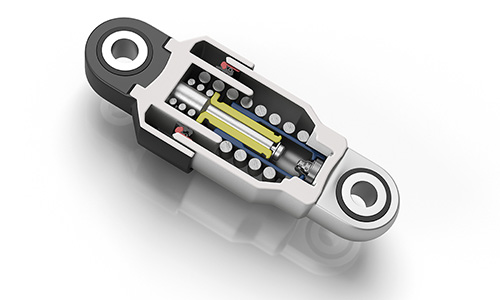

An NTN-SNR innovation – Variable damping hydraulic tensioner roller

NTN-SNR’s new adaptive tensioner roller, now makes it possible to:

- increase tension during the restart process then reduce the tension to help stop wear to the system components.

- function in its role as tensioner-damper (compensating for the irregular motion of the engine and belt oscillation between the pulleys) with a minimum tension at all other times.

This small innovation helps reduce fuel consumption and extends the service life of the accessory system.

80% of the components used to in the new tensioner roller are identical to those of a conventional damper tensioner. This makes it much easier to incorporate the new damper roller design on to existing engines without any major changes.

For more information about "Stop-Start" engines, Consult the Press Release

Add new comment

Please, complete your details below.