LUBSOLID™ technology: revolutionalising all industrial sectors

In the 1990s, LUBSOLID™ technology emerged as a game-changer in the textile industry. It prolongs the lifespan of bearings by mitigating the premature failure caused by False Brinelling. Today, the technology is used across a wide range of industrial sectors to address the challenges encountered by professionals. (Re)discover this technology with undeniable advantages for industrial companies!

LUBSOLID™, a unique solid lubricant

70% of bearing failures are caused by poor lubrication: incorrect (too little or too much) lubrication quantities and the use of inappropriate lubricants etc. It was crucial to offer a lubricant capable of mitigating these failures.

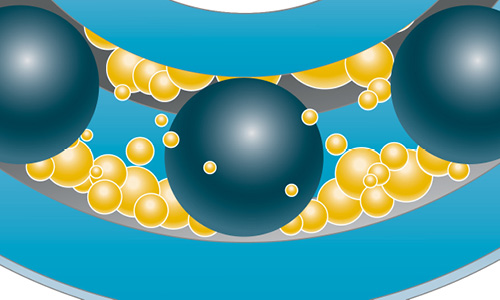

LUBSOLID™ first revolutionised the bearing lubrication process in the textile industry. The lubricant consists of a polymer matrix that fills the free space inside the bearings.

- The porous polymer matrix contains a large amount of oil. The lubricating oil is gradually released due to the thermal and mechanical stresses exerted on the bearing. This way, the contact between the track and the rolling stock is continuously lubricated.

- When the bearing is no longer in use, the temperature drops, the force applied to the matrix is reduced and, like a sponge, the matrix reabsorbs the oil.

Ultimately, the matrix structure retains, distributes, and reabsorbs the oil according to the operation of the bearings.

The benefits of LUBSOLID™ technology

Thanks to its solid formulation and its ability to release then absorb oil, LUBSOLID™ comes with a lot of advantages.

Prolonged equipment lifespan

LUBSOLID™ is a lifetime lubricated solution that offers superior durability compared to its grease-filled counterparts. In certain application conditions, the observed lifespan has been multiplied by 20.

Little or no maintenance

Thanks to its maintenance-free nature and its ability to increase bearing lifespan in numerous applications, LUBSOLID™ eliminates the need for greasing and extends the replacement intervals for parts.

Less operating and maintenance costs

Maintenance costs are reduced by eliminating the need for lubrication and by spacing out maintenance operations.

Limited environmental impact

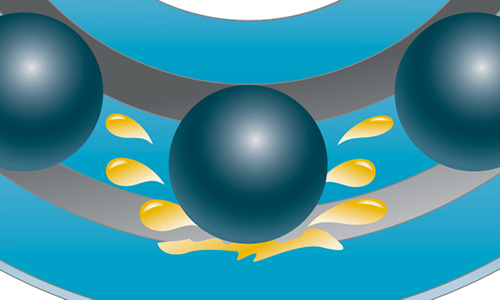

The LUBSOLID™ matrix retains the lubricant, preventing leaks into the environment, particularly in outdoor applications such as agriculture and mining. Moreover, thanks to the extended lifespan, each industrial user reduces their consumption of bearings (resulting in less steel usage) and grease.

Clean production line

By retaining the lubricating oil, the LUBSOLID™ matrix, eliminates leaks in production and workshop environments, as observed in industries such as food processing and metalworking.

Suitable for all bearing types

From ball and insert bearings to spherical roller, cylindrical, or needle bearings, with or without cages, open or sealed, etc., LUBSOLID™ meets the lubrication needs of various bearing types, even in the harshest environments.

A lubrication technology for all industrial markets

In the 1990s, LUBSOLID™ technology met the needs of the textile industry at that time. In recent years, NTN Europe has sought to expand its presence in other industrial markets.

Since 2017, a dedicated range of bearings with solid lubricant has been offered for the food industry, to meet rigorous hygiene standards. With its unique NSF-H1 certified formulation, it complies with the current sanitary standards in this sector.

In 2023, to meet the needs of various industrial sectors, NTN Europe set up a new production line dedicated to filling bearings with LUBSOLID™ technology. This is good news for industrialists, as it reduces tooling costs, makes production more flexible and opens up new market opportunities.

Industrial companies, discover a solid lubricant tailored to your needs. Make your equipment safer, make substantial savings, and preserve your equipment with LUBSOLID™!

Add new comment

Please, complete your details below.