Increase the availability of your machine through our innovative range to offer news features and a new experience within the field of monitoring.

Monitoring system: to cover all your monitoring requirements

In addition to the ordinary vibratory analysis, NTN-SNR has developed a magnetic technology to measure a varied speed range (especially at very low speeds) in vibrating and difficult to access environments, all at an optimised cost level.

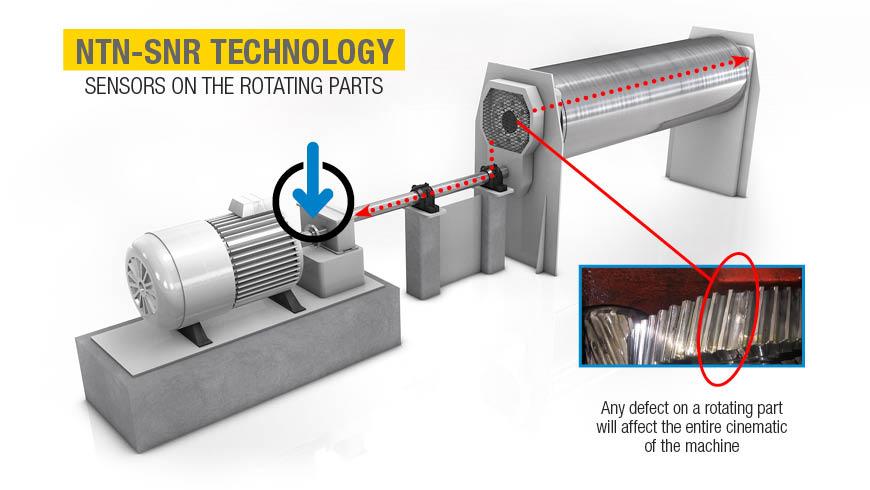

A technology based on an innovative principle

Diagnostics of rotating machines have been available for several decades, and they often involve measuring machine vibrations using sensors placed on the fixed parts (bushings, frames, structures, etc.).

Breaking with this approach, our magnetic technology can be used to make very precise measurements of operating variations in rotating parts.

Developed specifically by NTN-SNR, our magnetic sensors measure in real time the multidirectional magnetic fields given off during shaft rotation to provide a clear, legible picture of the full drive system.

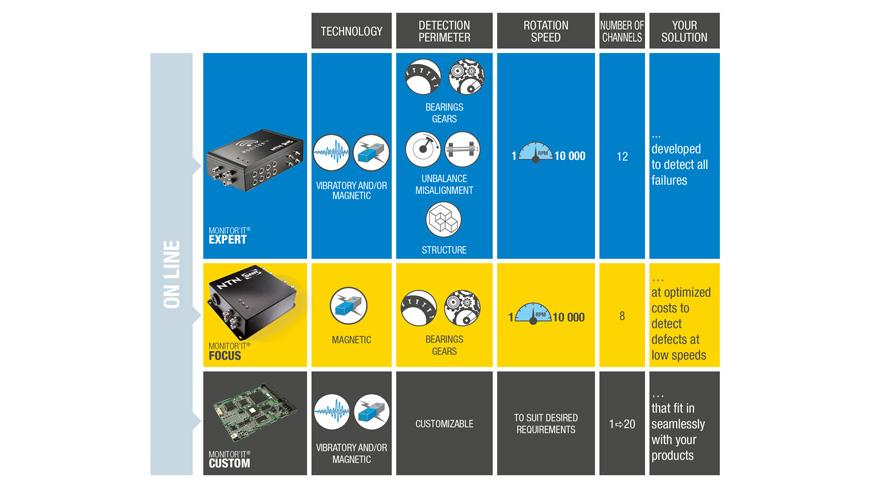

Our range of MONITOR’IT®

MONITOR’IT EXPERT: a combination of two magnetic and vibratory technologies

The MONITOR’IT® EXPERT solution has been developed to detect all failures and monitor all mechanical elements, whether they are on bearings, gears or the structure.

By making the most of two technologies, magnetic measurement developed by NTN-SNR and ordinary vibratory analysis, MONITOR’IT® EXPERT not only enables you to detect defects at very low speeds (5rpm) but also to avoid potential failures affecting structures, incipient unbalance and misalignment problems that are found in metalworking industries, mines and quarries, paper mills, and more generally in all processing industries.

MONITOR’IT FOCUS: an innovative magnetic technology

The MONITOR’IT® FOCUS solution has been developed in a context of optimum cost-performance ratios to monitor and detect all types of defects present on bearings and gearing teeth in complex environments.

The magnetic technology developed by NTN-SNR can be used to detect defects at the very low speeds (5 rpm) found in the metalworking industries, mines and quarries, paper mills, and more generally in all processing industries.

This technology also makes it possible to take remote measurements and detect of all types of defects present on drive systems in areas that are difficult to access, by positioning the sensors remotely as compared with the area to be monitored.

MONITOR’IT CUSTOM: a set of technologies (magnetic, vibratory, etc.) to be defined to suit your requirements

The MONITOR’IT® CUSTOM solution has been developed to adapt to all your products, whatever their configuration and their environment. Your product self-diagnoses through implementation of a software component or a PCB.

We examine each case in detail to be sure to meet your requirements on an exhaustive, pertinent basis, whatever your field of application.

A widened MONITOR’IT® offering to cover all your monitoring requirements

Would you like to download the MONITOR’IT® catalogue? SEND YOUR REQUEST

Do you have any questions? CONTACT US