Discover our range of tapered roller bearings: reliable performance and the advantage of a complete range in both imperial and metric dimensions.

NTN, a key player in tapered roller bearings, heavily involved: 100 million units produced each year in the world and a large storage capacity in our European warehouse, which is 100% dedicated to the industrial market.

Why choose our tapered roller bearings?

Because of their strengths, NTN and SNR tapered roller bearings offer interesting opportunities in many markets, such as agriculture, rail, communications, steel, wind energy …

Safety: the commitment and experience of a premium brand

NTN plays a leading role in the bearing industry. Going beyond the design and production of bearings, we have been recognized for nearly 100 years for our ability to innovate. Uncompromising about the quality of our products, we closely monitor the manufacturing process at our production sites in Japan, France and the United States.

Choice: a complete range

Our offer contains more than 3000 references, in imperial and metric dimensions, covering the entire core range. In addition, our engineers also develop tapered roller bearings customised to the specific needs of your markets (wind energy, railway, agriculture…).

Quality: high performance steel

We offer several types of steel for tapered roller bearings. Our standard? Carburizing steel, hard on the surface and ductile in the core to better absorb shocks and increase useful life. When used in arduous applications such as mines and quarries, we are able to achieve a 40% increase in service life thanks to this steel.

What is the major advantage of tapered bearings? 100% of the imperial range is made from carburizing steel!

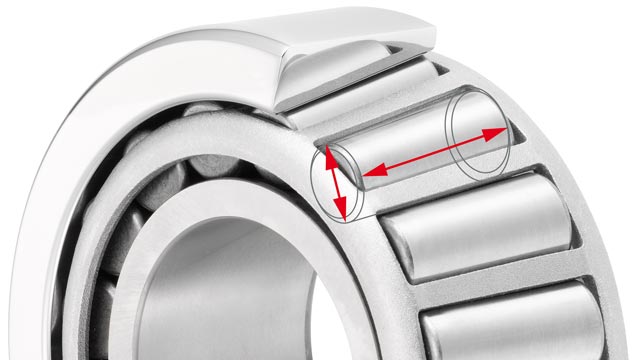

Tapered roller bearings: specificities of the NTN and SNR range

Standard dimensions:

- metric: up to 850mm bore

- imperial: up to 1400mm bore

For specific applications our tapered roller bearings can measure up to 4m in diameter!

Rows:

- 1, 2 or 4 rows

Mounting:

- in X or O configuration according to the loads applied

- convenient due to separable cup and cone

Steels and heat treatments:

- carburizing or carbonitriding to improve properties: surface hardness, dimensional stability, resistance to temperature changes

- through hardened steel

Some benchmarks of the range:

- T7FC and 303xxD: our two series with steep angles (angle >24°).

Particularly suitable for hydraulic pump and motor applications as well as pinion driveshafts for agricultural transmissions.

Prefixes and suffixes to take note of:

- prefix 4T for carburized steel, adapted to extreme conditions. Available on almost all of the range

- suffix U for through hardened steel (NTN brand products)

Would you like to learn more about tapered roller bearings? Take a look at our BROCHURE Access the CATALOGUE

Discover the range Access the e-Shop

The NTN guarantee: in the words of our expert

NTN - SNR has continually increased the static and dynamic capacities by increasing the number and the size of rollers in a bearing of the same size. Today, other avenues of development are being investigated, such as the profiles of the rollers and surface treatments.

For a tapered roller bearing 32207 for example, (older generation has 15 rollersand the next-generation has 17 rollers), with 2 additional rolls of a larger size, the gain in dynamic capabilities is 34%. This type of design is possible thanks to the optimization of the geometry of the cage, allowing the thickness of its bridges to be reduced, while improving its mechanical strength. One definite plus point of this example, is that the service life is increased by a factor of 2.65.

Need a tailor-made solution? CONTACT US