NTN Europe commits to sustainable mobility with SNR refurbished driveshafts

- Annecy - Automotive Aftermarket - Products

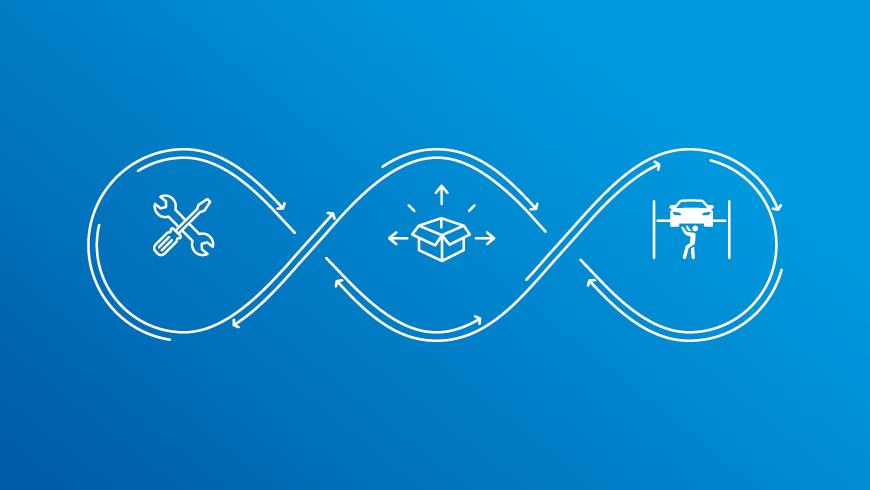

NTN Europe is committed to refurbishing driveshafts to meet the environmental challenges and requirements of a changing automotive industry. Designed with the circular economy in mind, the new range is the perfect response to the growing demands for sustainability and ecological responsibility.

SNR Renovated driveshafts: A circular economy solution

Aware of the importance of reducing carbon footprints and promoting the circular economy, NTN offers refurbished driveshafts as a sustainable alternative to new parts. This process allows the re-use of high-quality components, while ensuring performance and reliability equivalent to new products. By investing in refurbishment, NTN extends the life of parts, reduces waste and supports more responsible mobility.

In this way, NTN enables garages to offer their customers a diversified and environmentally friendly range, in line with the AGEC law of 10 February 2020 (Anti-waste for a circular economy), which encourages the use of spare parts from the circular economy whenever possible.

A rigorous process for guaranteed quality

NTN's driveshafts remanufacturing process is based on 10 rigorous stages, from the collection of ‘cores’ (used parts) to the final performance tests, to guarantee a quality equivalent to that of new parts.

Each driveshafts undergoes complete disassembly, followed by meticulous cleaning to eliminate any contamination. Worn components, such as bellows and clamps, are systematically replaced, and some critical parts are remanufactured to their original condition.

Driveshafts are then reassembled by hand to ensure a perfect fit. Finally, each product undergoes strict performance and durability tests before being painted and packaged.

The refurbished parts market: growth driven by eco-responsible demand

The market for refurbished parts is experiencing strong growth, driven by a growing awareness of environmental issues and a constant search for more sustainable solutions. Companies, aware of the environmental and financial benefits, are turning to circular solutions, stimulating demand for refurbished products that are both reliable and environmentally friendly.

“As a manufacturer of new driveshafts, we know this market well. Refurbished driveshafts are playing an increasingly important role, driven by refurbishers who have been developing their expertise in this product since 2000. They now account for 30 to 40% of the available range, with excellent prospects for growth.”

With the launch of its range of renewed driveshafts, NTN Europe is demonstrating its commitment to sustainable and responsible mobility. It responds to current ecological and economic challenges while offering customers a reliable, high-performance alternative to new parts.

NTN and Ducati: a historic partnership now made official

- Annecy - Automotive Aftermarket - Events

<div class="az-element az-section container-fluid-wrapper" style="" data-dxpr-builder-libraries="" data-az-id="gbknd0masq" data-azat-pid="gbknd0masq" id="gbknd0masq" data-azb="az_section" data-az-human-readable="Section" data-… Read more

NTN unveils its new range of bearing lubricants, the result of 100 years of expertise

- Europe - Industry OEM - Products

SNR is launching a new range of professional greases, marking a new milestone in the optimisation of industrial maintenance. The brand is drawing on its 100 years of experience to offer a high-performance, durable, easy-to-use and more environmentally friendly range to meet the challenges of tomorrow.… Read more