As a trusted partner to industry players, NTN develops critical bearings for the most complex aerospace applications.

Reliability, innovation and responsiveness guide every solution designed for safety and performance.

High technology

Hybrid bearings, superfinishing,

advanced materials

French manufacturing

High-precision production on site in Haute-Savoie

Customised performance

Adapted to mechanical and environmental constraints

Technical partnership

Co-development,

industrialisation, support

Bearings designed for aerospace requirements

NTN designs customised bearings for every environment, combining tribological expertise, advanced material selection and geometric optimisation. Our engineers take specific constraints into account right from the design stage: temperatures, rotational speeds, low lubrication, space requirements and misalignment.

This expertise is backed by a production site in France that integrates all special processes: superfinishing, heat treatment and non-destructive testing.

Solutions tailored to each application

Engines

Bearings for main shafts, gearboxes and accessory boxes.

NTN bearings for engines are designed to withstand high speeds and extreme thermal stresses. Their high-precision design ensures long-lasting, reliable performance, even under severe operating conditions such as those encountered on main shafts or during loss of lubrication.

Helicopters

Bearings for turbines, construction equipment, rear shafts, accessory housings, rotors, flight controls

NTN is a world leader in the design of satellite bearings for planetary gears used in helicopters. These bearings offer increased reliability, exceptional longevity and are suitable for high-performance transmission applications with severe load and vibration requirements.

Space

Bearings for cryogenic turbopumps and satellites

NTN bearings for cryogenic turbopumps and satellites are manufactured to withstand the most extreme conditions: intense vibrations, space vacuum and corrosive environments. Their robust design and high reliability make them ideal solutions for high-tech space missions.

Aeronautical equipment

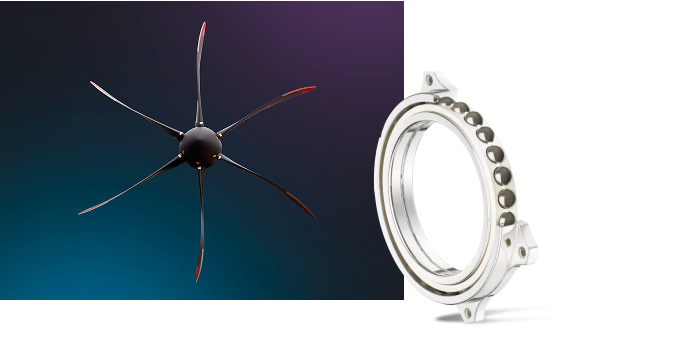

Bearings for propellers, starters and generators

Our bearings for aerospace equipment are specifically designed to ensure reliable and long-lasting performance, even under low lubrication levels and in harsh electrical environments. Their robustness and precision make them ideal for critical systems.

New technology and new mobility

Bearings for eVTOL, hybrid propulsion and electric motors

NTN offers bearings for new mobility applications, including eVTOL, hybrid propulsion and electric motors. With hybrid ceramic materials (Si₃N₄), our bearings offer excellent insulation, increased compactness and the lightness essential for advanced mobility applications.

Co-developing critical solutions with precision and rigour

At NTN, every aerospace bearing is the result of collaborative engineering work carried out in close collaboration with our customers' design offices. Our experts are involved from the early stages to analyse the mechanical, thermal and environmental constraints specific to each programme. Prototyping, testing and validation: every step is guided by technical rigour, agility and attentiveness to ensure reliable, high-performance solutions that are perfectly suited to the requirements of the aerospace industry.

The Made in France

Commitment

"Made in France" is a guarantee of quality and expertise. NTN Europe has chosen to design and manufacture its aerospace solutions in France, at its dedicated aerospace site in Argonay, to ensure high-performance products that comply with strict industry standards and to support local innovation. This approach ensures total control of production processes and optimal traceability, while strengthening the economy, expertise and competitiveness in the European market.

Sustainable innovation

Each innovation has a dual objective: performance and reduced environmental impact. We are contributing to the transition of the aerospace industry with:

- Innovative materials (ceramics, hybrids)

- Reduced weight and friction

- Longer component life

As such, we are recognised by the CleanSky Europe programme.

Support throughout the

product life cycle

Design, series production, MRO, training

Our teams are there every step of the way to guarantee

the long-term reliability of components.

Brochures

Discover our solutions and services for the aerospace industry.

Let's build your solution together

Our experts will help you choose the right bearings